HOW WOOD IS FORMED IN TREES: This online article has been adapted from the printed chapter “What is Wood?” in the book WOOD! Identifying and Using Hundreds of Woods Worldwide by Eric Meier. A hard copy of the book is also available for purchase.

HOW WOOD IS FORMED IN TREES: It’s common knowledge that wood comes from trees. What may not be so apparent is the structure of the wood itself, and the individual components that make up any given piece of lumber. Unlike a mostly homogenous piece of foamboard, MDF, or other man-made material, wood is an organic material, and has many distinct characteristics which will be helpful to learn.

HARDWOODS AND SOFTWOODS

An immediate and broad distinction that can be made between types of trees (and wood) is the label of hardwood or softwood. This is somewhat of a misnomer, as the label is actually just a separation between angiosperms (flowering plants such as maple, oak, or rosewood), and conifers (cone-bearing trees such as pine, spruce, or fir). Hardwoods (angiosperms) have broad-leaved foliage, and tend to be deciduous—that is, they lose their leaves in the autumn. (However, many tropical hardwood species exist which are evergreen—they maintain their leaves year-round.) Additionally, hardwood trees tend to have a branched or divided trunk, referred to as a dendritic form.

Softwoods (conifers) tend to have needle or scale-like foliage, though in some uncommon instances, they can have rather broad, flat leaves, such as Kauri (Agathis australis). Most softwood trees are evergreen, however, some conifers such as larch or cypress lose their foliage in the autumn, (hence the common name “bald-cypress”). Softwoods tend to have a single, dominant, straight trunk with smaller side branches, referred to as an excurrent form—this cone-shaped growth form helps trees in temperate climates shed snow. Again, there are several conifers that are an exception to this growth form, such as Cedar of Lebanon (Cedrus libani).

The confusion in labels arises in that the wood of angiosperms is not always hard (a glaring example is Balsa, which is technically classified as a hardwood), while the wood of conifers is not necessarily always soft, (an example of a relatively hard softwood would be Yew). However, as a rule of thumb, hardwoods are of course generally harder than softwoods, and the label is still useful to distinguish between two broad groups of trees and certain characteristics of their wood.

TREE GROWTH

To start off with, let’s suppose that we have a tiny little sapling, just starting out on its journey to become a grand tree. Besides the basics of the roots, the main stem (trunk), and the leaves and branches, there are growing points at the tips of the stems and roots, called apical meristems. These growing points, through cell division, are responsible for the vertical growth in trees. Additionally, sandwiched between the bark and the inner wood is a thin layer or sheath called the vascular cambium or lateral meristem—usually referred to simply as the cambium. This tiny, seemingly magical layer is responsible for practically all of the horizontal growth on a tree. The cambium consists of reproductive cells that, by cell division, forms new bark outward, and also new wood inward. It is the seasonal growing activity of the cambium that is responsible for the formation of growth rings seen in wood: in temperate zones, the cambium is most active in the spring, (this wood is sometimes referred to as springwood or earlywood), with growth slowing in the summer, (called summerwood or latewood), and completely ceasing in the winter. These differences in growing cycles from year to year form annual rings, which are a reasonably accurate indicator of a tree’s age.

| Softwoods: latewood tends to be darker, denser, and has smaller diameter tracheids; earlywood is lighter, softer, and has larger diameter tracheids | Hardwoods (ring-porous): latewood has smaller and less frequent pores; earlywood has larger, more numerous pores |

| Redwood (endgrain 10x) | Paulownia (endgrain 10x) |

| Note the much wider earlywood zone in softwoods such as the Redwood (Sequoia sempervirens) pictured on the left as compared to hardwoods like Paulownia (Paulownia tomentosa) on the right. When a tree grows slower than average, (perhaps due to an unfavorable growing site), the earlywood and latewood zones become condensed. This difference explains why slower growing softwoods tend to be stronger, (the weaker earlywood zones are narrower), while slower growing ring-porous woods like oak or ash tend to be weaker, (the stronger latewood zones are narrower). |

In tropical zones, where temperature and seasonal variations are minimal, wood can completely lack discernible rings, or they may correspond with various rainy seasons, and thus are more safely referred to as growth rings, and not strictly as annual rings.

An endgrain view of Avodire (Turraeanthus africanus), a tropical African hardwood species, reveals an overall lack of discernible growth rings or earlywood and latewood zones.

SAPWOOD AND HEARTWOOD

As the cambium forms new wood cells, they develop into different sizes, shapes, and orientations to perform a variety of tasks, including food storage, sap conduction, trunk strength, etc. When a tree is young, certain cells within the wood are alive and capable of conducting sap or storing nutrients, and the wood is referred to as sapwood. After a period of years, (the number can greatly vary between species of trees), the tree no longer needs the entire trunk to conduct sap, and the cells in the central part of the stem—beginning at the core, or pith—begin to die. This dead wood which forms at the center of the trunk is thus called heartwood. The transition from sapwood to heartwood is accompanied by the accumulation and buildup of various deposits and substances, commonly referred to as extractives. Most notably, these extractives are responsible for giving the heartwood its characteristic color: the jet-black color of Ebony (Diospyros spp.), the ruby-red of Bloodwood (Brosimum rubescens), or the chocolate-brown of Black Walnut (Juglans nigra)—all owe their vivid hues to their respective heartwood extractives. (Without extractives, the sapwood of nearly all species of wood is a pale color, usually ranging from white to a straw-yellow or grey color.)

Heartwood extractives, like those found in this sample of Tulipwood (Dalbergia decipularis) provide a cornucopia of colors and unique wood properties. But heartwood extractives are responsible for more than just color; extractives increase (to varying degrees) the heartwood’s resistance to rot and decay, as well as giving it added stability and hardness. (Sapwood has virtually no resistance to decay—which, being essentially alive in the tree, is not needed.) From a biological standpoint, it’s easy to see the benefits that heartwood brings to the tree as it grows taller and broader—and incidentally, many of these same benefits translate into advantages for woodworkers as well. However, it should be noted that the transition area from sapwood to heartwood, commonly referred to as the sapwood demarcation, can vary from gradual to very abrupt: this can be important in wood projects where decay resistance is needed. A clear line of demarcation helps prevent the inadvertent inclusion of sapwood, and minimizes the risk of subsequent rotting or structural damage.

| Black Walnut (sapwood demarcation) | Amazon Rosewood (sapwood demarcation) |

| Notice the very subtle transition from sapwood to heartwood on the sample of Black Walnut (Juglans nigra) as compared with the very sharp line of demarcation on Amazon Rosewood (Dalbergia spruceana). |

PLANES OR SURFACES OF WOOD

When discussing processed wood and lumber, it’s necessary to understand which surface of the wood is being referred to. Working within the scope of growth rings already discussed, and their orientation within the tree’s trunk, there are three primary planes, or surfaces, that are encountered in processed wood. The first wood surface is the endgrain, (which is by far the most useful plane for wood identification purposes). This surface is sometimes referred to as the transverse surface, or the cross section. This plane is mostly self-explanatory: in processed lumber, it’s the section where a board is typically viewed on its end, and circular growth rings may be clearly observed. For the sake of simplicity and clarity, all references on this website will refer to this wood plane as the endgrain. The second primary wood plane is the radial surface. (Think of the word radiate: the wood surface radiates out from the center of the log like spokes on a wheel, and crosses the growth rings at a more-or-less 90° angle.) This surface goes by a number of names, and is sometimes called vertical grain, or the quartersawn section. The reason for such naming is that when sawing a log, it may be sawn into quarters along the length of the log, forming four long, triangular, wedge-shaped pieces. Next, boards are sawn from each wedge on alternating sides, resulting in boards which—when viewed from the endgrain—have growth rings that are perpendicular to the face and run vertically. Again, for simplicity and clarity, most references on this website will refer to this wood plane as the quartersawn surface. This is perhaps not the standard scientific terminology used, but it’s the most common description used among sawyers and woodworkers. The third and final surface is the tangential surface. (Think of the word tangent: the wood surface is more or less on a tangent with the growth rings.) This plane is sometimes called the flatsawn or plainsawn surface. The reason for such naming comes again from the process of sawing the log. The normal or “plain” method of sawing a log is to cut straight through in a repetitious sequence, leaving the log flat throughout the entire process. (This is also sometimes called through-and-through sawing.) Most subsequent references on this website will refer to this wood plane as the flatsawn surface.

This sample of Butternut (Juglans cinerea) models the three wood surfaces well. Note the straight and consistent grain pattern shown on the quartersawn surface on the right as compared to the relatively wild flatsawn surface on top. The endgrain on the left shows the arc of the growth rings.

GRAIN APPEARANCE

Although quartersawn and flatsawn surfaces are named after their original method of sawing, in practice, the terms typically just refer to the angle of the growth rings on a piece of processed lumber, with anything between 45° and 90° being referred to as quartersawn, and anything between 0° and 45° generally being flatsawn, regardless of how the log was actually milled. There’s sometimes an intermediate angle commonly called riftsawn or bastard grain, which corresponds with growth rings angled between 30° to 60°, (with 45° being the average). Although it is called riftsawn, sawyers will rarely if ever specifically saw up a log in order to get such an angle; usually the name merely serves as a convenient term to describe wood that is not perfectly quartersawn. Additionally, the term face grain usually denotes the most predominant/widest wood plane on any given piece of lumber (excluding the endgrain), and does not refer to any specific cut. By observing the angle of the growth rings—as when looking at a stack of boards where only the endgrain is visible—a reasonably accurate prediction of the appearance of the face of the board can be made. Likewise, in many instances where only the face of a board is visible, the endgrain may be extrapolated by “reading” the grain pattern. Each grain cut has varying strengths and weakness, and is used in different applications.

| Reading the Grain | ||

|  |  |

| Beli | Ponderosa Pine | Western Hemlock |

| Note the appearance of each of the faces of these three boards, as well as their corresponding endgrain surfaces beneath. On the left, Beli (Julbernardia pellegriniana) is almost perfectly quartersawn, resulting in a straight, narrowly-spaced, and uniform grain pattern. In the middle, Ponderosa Pine (Pinus ponderosa) is flatsawn, resulting in a characteristic “cathedral” grain pattern. On the right, Western Hemock (Tsuga heterophylla) has a section on the left that is flatsawn, grading down to riftsawn, as reflected on the face of the board, which appears flatsawn on the wild portion on the left, and closer to quartersawn on the straighter and more uniform portion on the right. |

Quartersawn boards are very uniform in appearance and are good for long runs of flooring where the boards need to be butted end-to-end with minimal disruption in appearance. Quartersawing also produces the stablest boards with the least tendency to cup or warp with changes in humidity, which is very useful in many applications, such as for the rails and stiles of raised panel doors. However, because of the extra handling involved with processing the log, and the higher waste factor, quartersawn lumber tends to be more expensive than flatsawn lumber. Most would agree that flatsawn boards—with their characteristic dome-shaped cathedral grain—tend to yield the most visually striking patterns, (and it should come as no surprise that many veneers are also rotary-cut from logs to reproduce this appearance). Flatsawn boards are also available in wider dimensions than quartersawn stock, and are well-suited to applications such as raised or floating panels, or other areas where width or appearance are important. Riftsawn wood lies somewhere between these two aforementioned grades. It has a uniform appearance that is very similar to quartersawn wood—and it’s nearly as stable too. On large square posts, such as those used for table legs, riftsawn wood has the added benefit of appearing roughly the same on all four sides, (since the rings on each of the surfaces are all at approximately 45° angles to the face), whereas quartersawn squares would have two sides that display flatsawn grain, and vice versa.

RAYS

A discussion on quartersawn and riftsawn lumber would not be complete without mentioning the most significant visual distinction between the two: presence (or absence) of rays; or perhaps more accurately, the conspicuous presence of rays on the face grain of the board, known commonly as ray fleck, or ray flakes.

|

| Note the lighter colored rays radiating out from the pith in this sample of Holm Oak (Quercus ilex). Ray fleck is only apparent in areas on the face of the board that are nearly perfectly quartersawn, with the flat and rift sawn areas on the left two thirds obscuring the rays under a lower profile. |

In the same way that quartersawn surfaces radiate out from the center of the log, (hence the term radial surface), rays are also oriented in the same direction; for this reason, although rays are always technically present in the wood, they become most visible and pronounced on quartersawn surfaces. (Additionally, endgrain drying checks also tend to occur along the rays.) But even though virtually all woods have rays, only the species with wide, conspicuous rays will produce dramatic ray fleck on the quartersawn surface. Perhaps the largest rays are found on woods like Leopardwood (Roupala spp.) and Lacewood (Panopsis spp.), so named for the superb ray fleck seen on their quartersawn surfaces.

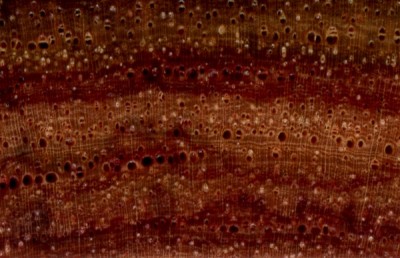

|

| The rays seen in this endgrain view of Lacewood (Panopsis spp.) are so large and prevalent, they could easily be mistaken for growth rings. |

Domestic woods like oak (Quercus spp.) and sycamore (Platanus spp.) also have easily observable rays; other woods have very modest yet visible ray fleck on quartersawn surfaces, such as Black Cherry (Prunus serotina). It should be noted that ray fleck is not always greeted with enthusiasm: the very same feature that may entice someone to purchase quartersawn oak may also repel another away. In some instances—such as for hardwood floors where a subdued or consistent grain pattern may be desired—ray fleck may be viewed as objectionable or distracting. For this reason, riftsawn woods, most commonly White Oak (Quercus alba), are occasionally offered as a means to reap the benefits of uniformity and stability of quartersawn lumber without the sometimes detracting rays.

GET THE HARD COPY

If you’re interested in getting all that makes The Wood Database unique distilled into a single, real-world resource, there’s the book that’s based on the website—the Amazon.com best-seller, WOOD! Identifying and Using Hundreds of Woods Worldwide. It contains many of the most popular articles found on this website, as well as hundreds of wood profiles—laid out with the same clarity and convenience of the website—packaged in a shop-friendly hardcover book.